|

DFW's Largest Custom Sign Company |

||||

|

Call Now! We're waiting!

Our Team of Experts are standing by to Answer Your Questions: (877) SINCE79 toll-free (214) 339-2227 Dallas (817) 861-1234 Fort Worth/Arlington (972) 850-3300 Other DFW Areas (254) 582-7446 Hillsboro/Waco Areas (903) 561-5959 Athens/Oklahoma (940) 365-3433 Denton/North Texas Email our Sales Team: |

||||

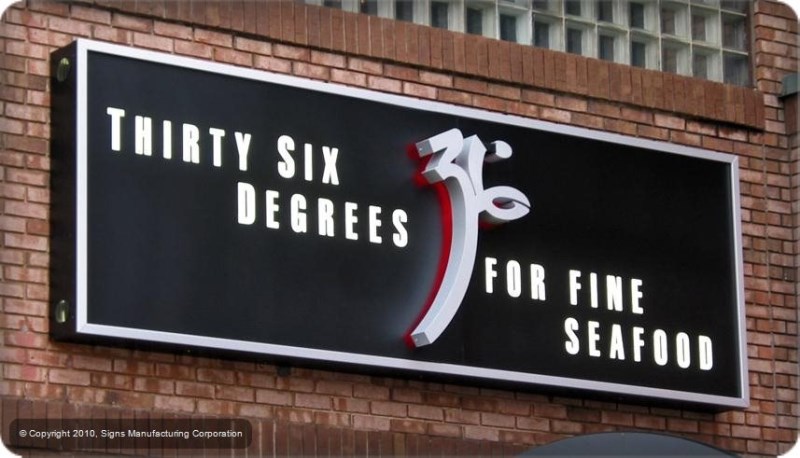

Electrical for Wall Cabinet SignsOur illuminated wall signs are manufactured and installed to Underwriters Laboratories, National Electrical Code (National Fire Protection Association), and City Code standards using UL components and either LED lighting, "High Output" 800MA fluorescent, or H.I.D. lighting; depending on the size and shape of the signs, component cost, and the resulting electrical consumption.

H.I.D. lamps in our signs are

screened by proprietary lamp diffuser panels so "High Output" fluorescent burn brighter than standard fluorescent, and most importantly burn evenly in cold weather. H.I.D. lighting does not dim as much as fluorescent in cold weather. Both will light a sign equally when properly installed. Electronic fluorescent ballasts use less than half the energy of standard ballasts, and have proven their reliability. This is why we now use them! See our "Energy Savings" tab under "Lighting Choices." The fluorescent and H.I.D. ballast's used by Signs Manufacturing™ feature a TWO-YEAR warranty. Every ballast is individually fused to prevent one failed component from costing more in repairs than is necessary. Each fluorescent ballast also has a high-heat switch that automatically turns the ballast off until it cools to a safe operating temperature, important in preventing fires.

Electrical sockets for vertical fluorescent tubes are protected from water damage with "H" washers on each tube. A Signs Manufacturing™ sign's total wiring system is tested by a "Hi-Pot" test which insures that there are no wires which MAY short-out at a later date by testing them now with ten times their operating voltage. If neon is incorporated into the sign, glass neon electrode housings are employed wherever possible to increase reliability and improve the appearance of the sign. To help prevent fires, the National Electric Code and Underwriters Laboratory require that all large signs containing neon use ground-fault protected neon transformers.

Signs Manufacturing™ uses "France" standard neon transformers because unlike ALL other transformers these U.S. manufactured transformers contain a "Smart" microprocessor that automatically tries to reset the ground-fault before shutting down the transformer. If the fault was only momentary, the transformer will remain "on," illuminating your sign. These transformers also automatically reset when their power is turned off and then back on. They offer our customers the greatest opportunity to avoid service calls. Our newly-developed energy-saving in-series transformers also contain “Smart” microprocessors. The related costs of the two different types of transformers with neon lighting, as well as LED lighting, is explained under our "Neon/LED Energy" tab under our "Lighting Choices" tab.

Translux high-voltage silicone-insulated wire will be used during neon installation, even though it is four times more expensive than some neon wire, to insure against transformer “nuisance tripping”, arcing, fires, and potential service calls caused by neon transformer outputs as high as 15,000 volts. Glass tube/wire supports and porcelain insulators will be used because they do not degrade over time, unlike the plastic and clay components used by some. LEDs are very sensitive to voltage. The power supplies we use to power LEDs provide internal overvoltage, low voltage, spike and brownout protection for the sign. Many manufacturers do not. Please stop by and see all of these products displayed in our unique Sign Lighting Laboratory and Display Showroom. Zap Protection™ - Optional Electrical Surge and Lightning ProtectionElectrical surges on a sign’s incoming power supply, and lightning strikes, are not covered by any manufacturer’s warranty, and they are common in Texas. As technology has moved us from the use of electrical components such as core-and-coil ballasts to electronic components, primarily to reduce power consumption, the susceptibility of a sign to damage from electrical power surges or lightning strikes has increased dramatically. Old-style electrical components are simply no longer available in most cases. Signs Manufacturing™ offers surge and lightning Zap Protection™, at a reasonable additional cost, adding components to signs to lower the potential for damage from an occurrence. 150 VRMS clamping volts for ground, 310 VRMS for line. Maximum surge current 100,000 amps, 0-400 Hz, UL Listed. NightLit™ Solar-Panel Lighting Option

So what can you do when it is cost-prohibitive to run power to a sign location? Signs Manufacturing™ created an affordable, attractive, unobtrusive answer. We created an outdoor, wet-location, sealed solar-panel and multiple-light combination pack specifically designed for signs. Patent and Listing Pending. NightLit™ lighting is designed to not be as bright as an advertising sign; it is designed to provide adequate, attractive lighting for identification, directional, and informational signage purposes.

An example of where it can be beneficial is building identification. Modern America searches for locations using computer assistance, and by address and suite/apartment numbers, primarily. Even while driving. The International Fire Code (IFC) 505.1 contains specific requirements for commercial building identification. Many AHJ’s (Authorities Having Jurisdiction) modify these basic requirements to require that building identifications, including both address and/or units identification where appropriate, be lighted to aid emergency service responders at night. Frankly, this requirement also aids package and food delivery companies (UPS, FedEx, Uber, Lyft, GrubHub, etc.) Many apartment and condo management companies use this amenity of user-friendly lighted building identification as a selling point to prospective dwellers who might have guests/deliveries trying to find their apartment at night. Specific to emergency response, some

AHJ’s require that lighted address identification remain lighted if the power supply to

the building is disrupted; a very good idea. But it has been very costly to

meet modified IFC 505.1 rules with existing structures because of the cost

of providing power and back-up power to retrofitting signage; until now. Increased safety and convenience at an affordable cost. Other uses?

It is relatively cheap, can be permanently custom-inscribed, custom-painted, UV-protected, vandal-resistant-coated, repairable, and readily available! There are, however, size and design restraints on this technology. Discuss your vision with us; since we’re the ones who created NightLit™ we’re the experts. We’ll create a way to make it work for you. Our initial product requires a 24-36” cabinet length, and a height of 15” or less. Electrical Circuits for (almost) All SignageThe National Electrical Code (NEC) adopted by the State of Texas, and virtually every Authority Having Jurisdiction (AHJ) requires that circuits serving electrical signs be 20 amp. maximum, and serve no other device. This includes the common wire, and the ground wire (the white and green wires.) If the signage contains neon the circuit can be rated up to 30 amp. The above was not always true, so it is possible that wiring serving older signs will need to be replaced by your electrician. Why? Signs used to basically be lights, running on lighting circuits, but this is no longer true. A modern electrical sign contains electronics, which includes Ground Fault Circuit Interrupter (GFCI) tripping. We have seen signs wired to older electrical circuits where turning on a fan inside a store turns off the exterior sign. NOTE: The Sunburst LED Signs™ we manufacture are fed by branch circuits, we distribute the electrical load inside the signage. Therefore, the circuit feeding our digital LED signs, or signage containing one of our Sunburst LED Signs™ are not constrained by this requirement. (Other manufacturers cannot do this.) Automatic Electronic Thermal Lighting Controls*We are often asked this question: "When I have our electrician run electrical power for our signs should I have him install a photo cell or a timer to turn it on and off?" When our founder was very young he managed a supermarket, a grocery store.He discovered that he could affect the store's business by simply turning “on” the store's signs on less-than-sunshiny days. Cloudy and/or rainy days would have a higher sales volume than bright days, IF HE REMEMBERED TO TURN THE SIGNS ON. And with the tinted window glass so prevalent in the South it is often-times hard to tell if a business is even open. These are lessons every business person should be aware of. And, with today's modern LED illuminated signage, it costs practically nothing to make your store really stand out! What is the main reason our Sunburst™ LED outdoor digital signs increase a store’s business so dramatically? Lighted signs draw much more attention than unlighted signs, even during the day!

The setting varies for signs pointed East, West, North, or South, and varies for signs containing neon, HID lighting, fluorescents, and/or LEDs. It also varies by how the sign was built. Our automatic electronic lighting controls are installed not only to recognize light levels, but also to sense shadows making signs less legible, and turn “on” the internal lighting accordingly. Optimum settings are custom-set for every sign. Another example of our doing everything we can to insure that our signs make your business the most successful. As far as we know, no other sign manufacturer does this, for free or otherwise, for their customers. If possible, have your electrician also wire a time clock to control the power supplying your signs. The time clock should be set to keep the sign “off” at times they should never be lighted, say 2:30 AM to 5:30 AM, the rest of the time whether the sign is “on” or “off” should be determined by our automatic lighting controls. USE ELECTRICITY WISELY TO MAKE YOUR BUSINESS THE MOST VISIBLE, BUT CONSERVE ENERGY. Regarding “Energy Consumption” note how little energy our SolarBrite™ LED lighted signs use in a year! Recognize that Intermatic and Tork time clocks, used by most electricians, are not finely adjustable, and at certain times of the year dawn and dusk occur at quickly-varying times, gaining or losing over 15 minutes of daylight each week. If you only have a time clock controlling power to your signs, savvy business owners must reset their time clocks constantly and carefully, and manually override them to turn “on” their signs on dark days. Good luck getting your employees to do this religiously – THIS IS ALSO WHY WE INCLUDE CALIBRATED AUTOMATIC THERMAL LIGHTING CONTROLS ON EVERY OUTDOOR SIGN WE MANUFACTURE.* Incidentally, we DO NOT use photo cells or photo eyes. They are neither precise nor reliable. Anecdotal data suggests that increased profits resulting from this feature alone more than pays for the entire cost of most signs EVERY YEAR. Unconvinced of the importance to you? View our control system in operation, and our supporting testing, in our Sign Lighting Laboratory and Showroom. Then you can decide if you agree that this is a critically important improvement in signage effectiveness. *Dependent on size and design. The failure mode for our automatic electronic lighting controls is “always on.” You will never be without an attractive sign if something should break; you’ll spend a little more on electricity until we get it fixed. What are Day-Light Designs™?Knowing that our signs will be illuminated during the day we design our signs and lighting for daylight effectiveness; to take full advantage of our daytime lighting. For instance, we pack backlighting to create a subtle glow during the day. If you are going to light a sign during the day the lighting better look good! This is easier to accomplish when we incorporate our SolarBrite™ LongLife™ LEDs which are so much brighter than competitive LEDs.

FOR ORDERING OR ASSISTANCE CALL:214-339-2227 254-582-7446 817-861-1234 903-561-5959 940-365-3433 972-850-3300 877-SINCE79 toll free

Business Hours Signs Manufacturing & Maintenance Corp.

Copyright© 1979-2025 Signs Manufacturing Corporation - ALL RIGHTS RESERVED

| ||||

Solar

panels are ugly and expensive.

Solar

panels are ugly and expensive..jpg)

.jpg)

_medium_110.jpg)